Sheroz Earthworks Fundamentals Explained

Sheroz Earthworks Fundamentals Explained

Blog Article

The Basic Principles Of Sheroz Earthworks

Table of ContentsSome Known Details About Sheroz Earthworks The Only Guide for Sheroz EarthworksSheroz Earthworks - TruthsExamine This Report about Sheroz EarthworksHow Sheroz Earthworks can Save You Time, Stress, and Money.

For any type of earthwork contractor, it is essential to do work with quality, accuracy, and on schedule. Using machine control in work machines allows optimizing the various phases in the earthwork procedure, from planning to the maintenance phase - fj dynamics auto steer price. The machine control system helps the machine operator in acquiring the target plane promptly and easily

The machine control system overviews the operator with centimeter accuracy. Remote assistance saves time and cash, as it minimizes downtime in jobsites.

The smart Trick of Sheroz Earthworks That Nobody is Talking About

Our system's parts are thoroughly made to endure the harsh problems of construction websites. Contrast of the same task performed making use of device control versus the typical method exposes that, on standard, the traditional technique calls for 50% even more time to accomplish the same task as the technology-assisted approach.

Get in the Xsite maker control system; it's below to supply you with a substantial advantage when working with earthmoving equipment. Discover exactly how Xsite Machine Control can improve your efficiency and make certain job safety! Xsite Device Control systems can be set up to any type of excavator from mini excavators to large mining excavators.

Exactly how does equipment control job? In 2D systems, the device is equipped with calibrated inclination sensing units. These sensors are mounted on the pre-determined components of the machine in excavators the sensor are usually placed to the framework, boom (or booms), digger arm and to the fast coupler - topcon. By utilizing the data obtained from these sensors the system can calculate the specific position of the excavators pail suggestion in relevance to a recommendation point.

The system is very simple to learn the fundamentals can be instructed in under one hour of training. With Xsite you do not need to bother with learning all the ideas and method at the same time. Extra training and guidelines are always offered over remote assistance when required. Contact your local Xsite dealership to figure out more! Just how does the remote support work? A wireless internet link makes it feasible to develop a remote link between the maker control system and the solution.

The smart Trick of Sheroz Earthworks That Nobody is Talking About

Xsite Device Control systems sustain open conventional file layouts, enabling seamless information circulation from one system to one more. Depending on your option of system (with or without positioning, i.e., 2D or 3D), your equipment is furnished with inclination sensing units, a controller system, and a display/operating panel.

Numerous software and hardware options exist to aid identify a machine's current placement on the earth and contrast it with a preferred design surfaceand construction drivers can do more to leverage the advantages. Device control is using numerous placing sensing units and a screen to supply the driver with a referral in between the setting of the bucket or blade and the target quality.

Depending upon the configuration, check over here machine control systems can supply the operator with a basic visual overview to pail or blade placement, or can instantly relocate the blade to quality by talking with the equipment's hydraulics - https://www.bark.com/en/au/company/sheroz-earthworks/370va/. There are equipment control systems readily available for simply concerning any equipment: graders, dozers, excavators, dirt and asphalt compactors, scrapers, leaners, crushing machines, and pavers

Examine This Report on Sheroz Earthworks

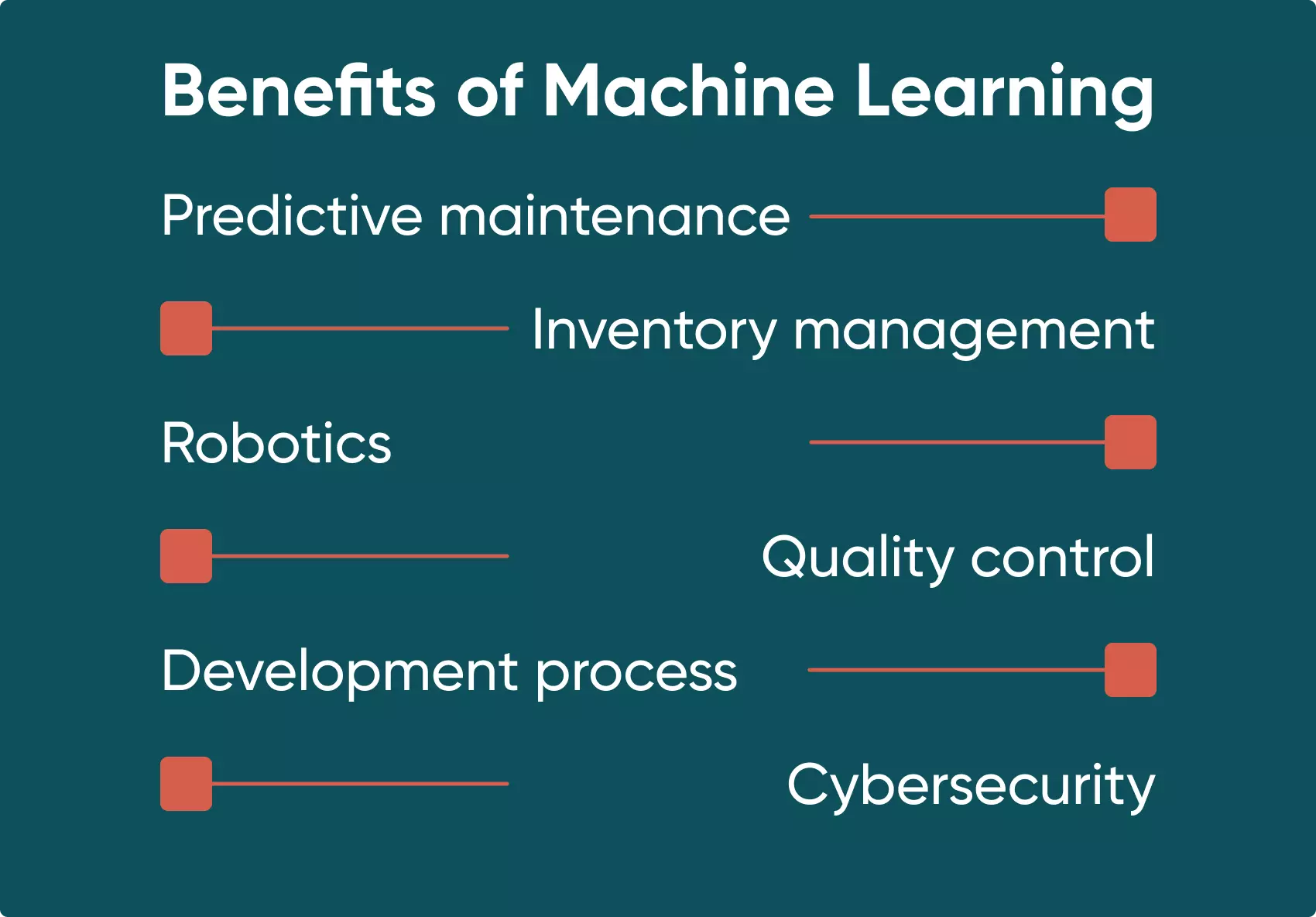

Device control can additionally assist increase performance and minimize overall expenses. Building tools without device control will certainly become a thing of the past and the benefits acquired from it will certainly be various.

Trimble machine control systems supply a myriad of benefits to any person who uses earthwork equipment and, at EarthCalc, we can supply you with 3D declare your equipment control-enable tools. Not exactly sure if device control is worth the cost? Consider the following reasons that you require to consider this alternative.

Utilizing general practitioner lined up with your 3D design documents, these systems essentially guarantee that you will certainly eliminate or place the correct amount of material at the building site. On many building and construction sites, revamp is a typical and frustrating truth, but with Trimble maker control, you can eliminate the demand for rework.

See This Report about Sheroz Earthworks

Typically, with Trimble equipment control, you can eliminate excess equipment at a certain work site. For instance, a work that may have needed making use of three or 4 items of digging deep into tools currently could require just 2 tools to achieve the very same job in less time. This enables you to move your devices to an additional work website and handle multiple jobs at one time.

Report this page